In a step towards broader commercialisation, Manifest Technologies has launched an evaluation kit to allow engineers and R&D teams to test and explore its Parallax Volumetric Additive Manufacturing (P-VAM) process.

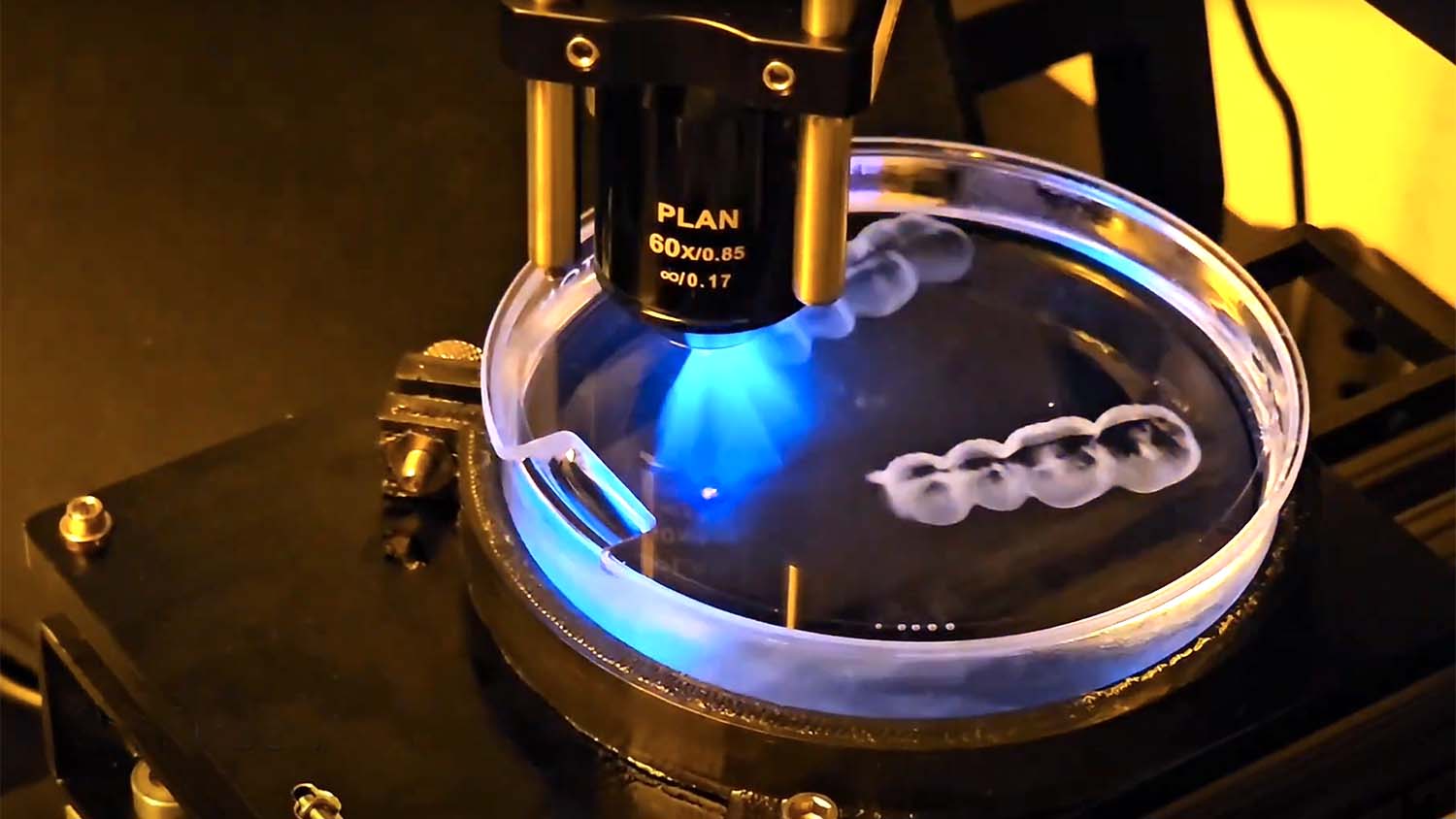

P-VAM uses a proprietary light engine and algorithms to cure photoreactive resin simultaneously across three dimensions, rather than layer-by-layer – completing objects in one continuous step with out need for supports.

An advanced manufacturing startup out of the University of Colorado’s McLeod Lab for Optics & Materials Science, Manifest Technologie simultaneously cures liquid resin in three dimensions, allowing users to build intricate, fully solid parts ’10 – 100x faster than conventional additive methods’.

Manifest Technologies says that P-VAM enables previously impossible geometries, including seamless embedding of electronics or objects directly within fabricated parts, while the resolution can be precisely adapted across individual components and unlimited horizontal scalability offering unprecedented flexibility for complex designs.

“We founded Manifest to fundamentally reimagine additive manufacturing – moving beyond layer-by-layer printing to instant, multidimensional formation of solid parts using precisely controlled beams of light,” said Manifset Technologies CEO and co-founder Camila Uzcategui. “At a time when the more mature additive technologies are beginning to stagnate, we view the debut of our P-VAM evaluation kit at RAPID as an invitation to forward-thinking partners to join us and manifest different.”

The P-VAM evaluation machine features a powerful light engine, advanced optics, high-power laser, precision Zaber stage, custom PCB, wiring, and robust casing, and comes pre-calibrated ready for immediate use. The machine is tuned to work with Arkema HT511 photopolymer material, a starter pack of which is included.

Manifest’s open platform approach allows users to experiment freely with a diverse array of transparent photopolymer resins, including high viscosity formulations, to precisely tailor materials to advanced applications.